Forging Your vision.

What characterizes our offer?

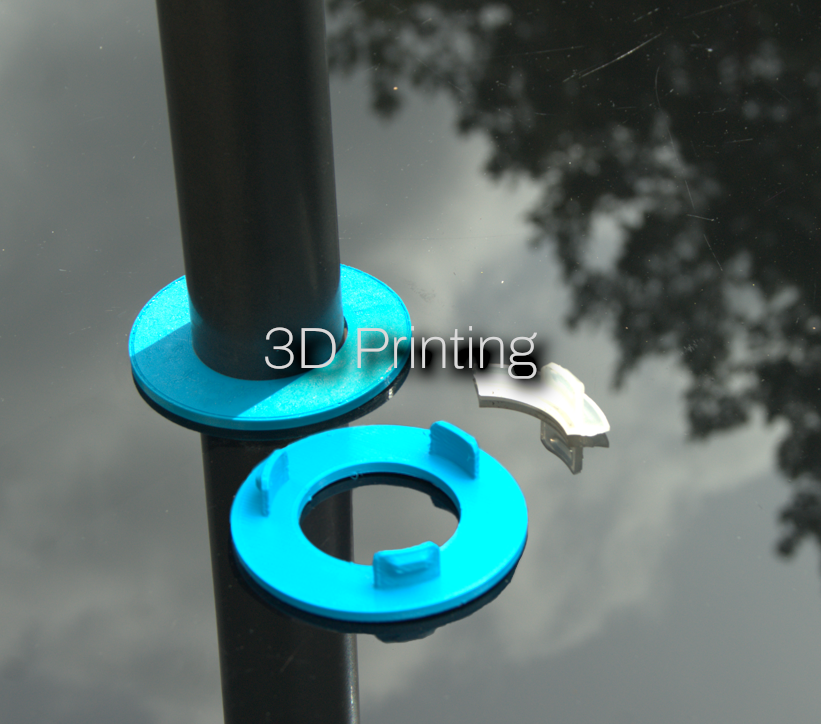

FDM 3D Print

MSLA 3D Print

Our resin printers operate on MSLA technology, where a UV light beam passes through a masking matrix to generate an image of the model. The filtered light then cures the photosensitive resin, resulting in highly detailed and sharp prints. We use printers with very high screen resolution, allowing for crisp and precise details. Resin printing technology enables us to achieve smooth walls with invisible layers and achieve very low dimensional tolerances of up to a hundredth of a millimeter. Therefore, we employ this technology when precision and visual aspects are crucial. From the perspective of individual parts, resin printing is slower compared to filament printing. However, MSLA technology compensates for this drawback by offering the ability to print multiple parts simultaneously, assuming they fit on the build plate. Since all elements are printed simultaneously, this significantly reduces the overall time required to print multiple items. The printing time is determined solely by the height of the printed object and printing parameters, with volume having no impact on it.

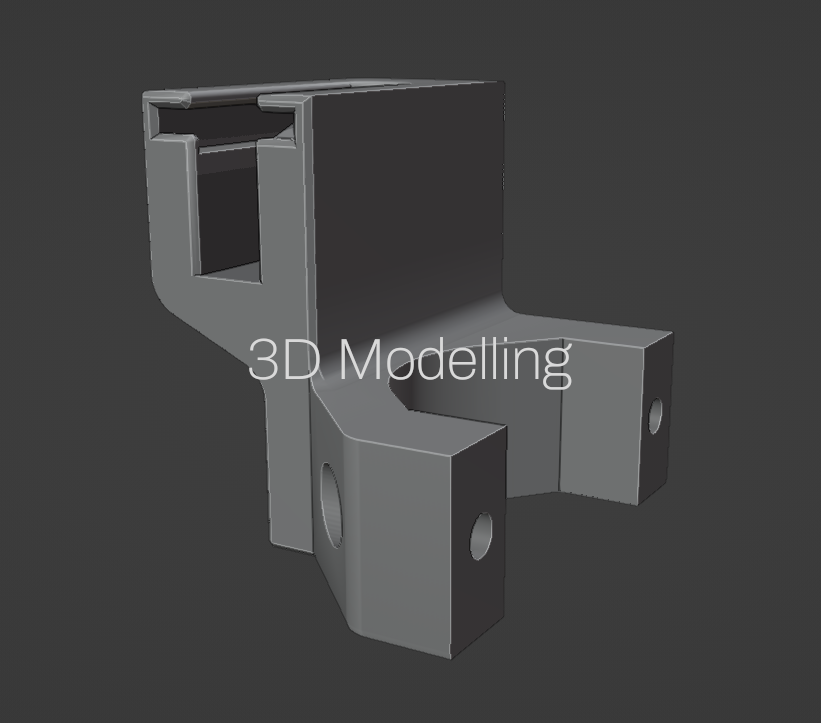

3D Modelling

We create ready-to-print functional models, including parametrically designed, “eye-balled” and artistic, based on inspirations, descriptions, and thematic patterns. We pay attention to the detail and geometric cleanliness of the models to ensure smooth printing processes. When necessary, the models are divided into components, and slots and sockets are added to facilitate easy reassembly of the parts. We offer both model creation services for printing on our in-house machines and the delivery of the finalized model to the client.

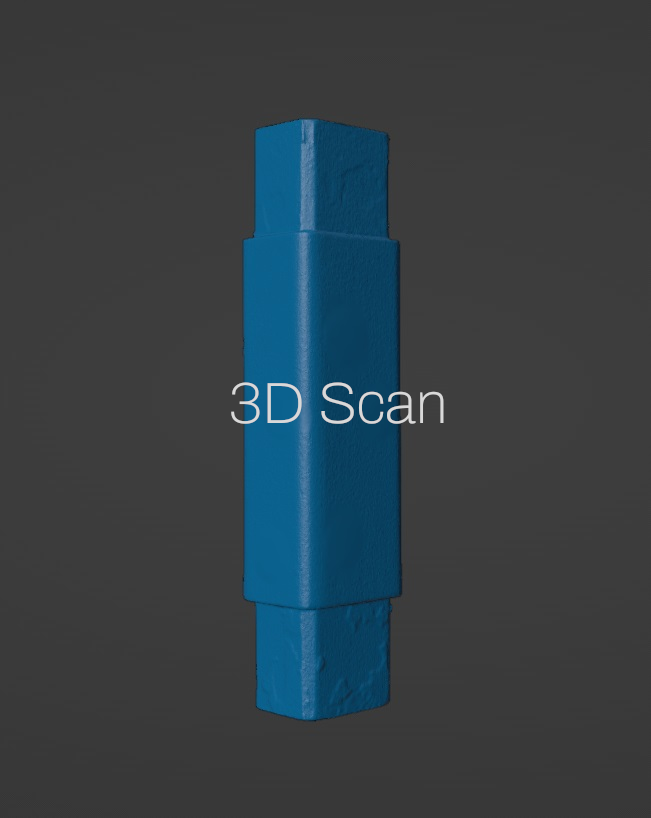

3D Scan

We utilize a structured light scanner, which allows us to scan objects with an accuracy of up to 0.05mm without the need for markers, as long as the object size does not exceed 200x200x200mm. For problematic, smooth, and reflective surfaces, we apply a non-destructive spray with a neutral substance suitable for all surface types. This substance is easily washable and leaves no trace behind. With the 3D scanner, we can create a model of an object, which can be used as an asset for gaming, to create replicas on a printer, or for reconstruction purposes and reverse engineering. We provide the raw scan result or perform post-processing and potential retopology.

Thanks to our experience and knowledge in optimizing the modeling and printing process, we are able to provide a wide range of products from various fields. Our expertise includes designing and creating precise 3D models, printing high-quality 3D prints, and customizing existing models to individual needs. We invite you to explore our full range of services on the subsequent pages, where we provide detailed descriptions of our capabilities and examples of our previous projects.